Product Spotlight on Repair Kits for Draper Header Belts and Baler Belts, Blog Post

Unexpected situations that cause minor tears or holes in equipment can happen in the field. While it’s never ideal, farmers can find themselves mid-season with a broken draper header belt or baler belt. Instead of ordering a new belt, Continental’s WCCO Belting line of products includes a repair kit for these pieces of equipment that can help farmers get through the season and which may even last the life of the original belt.

To learn more, we connected with Dan Larson, manager of customer service at the company’s Wahpeton facility, to talk about Continental repair kits that provide a quick “in the field” fix for farmers. Read on to learn about this technology and how it can help prevent extended downtime for farmers in a belting bind.

What exactly is a repair kit?

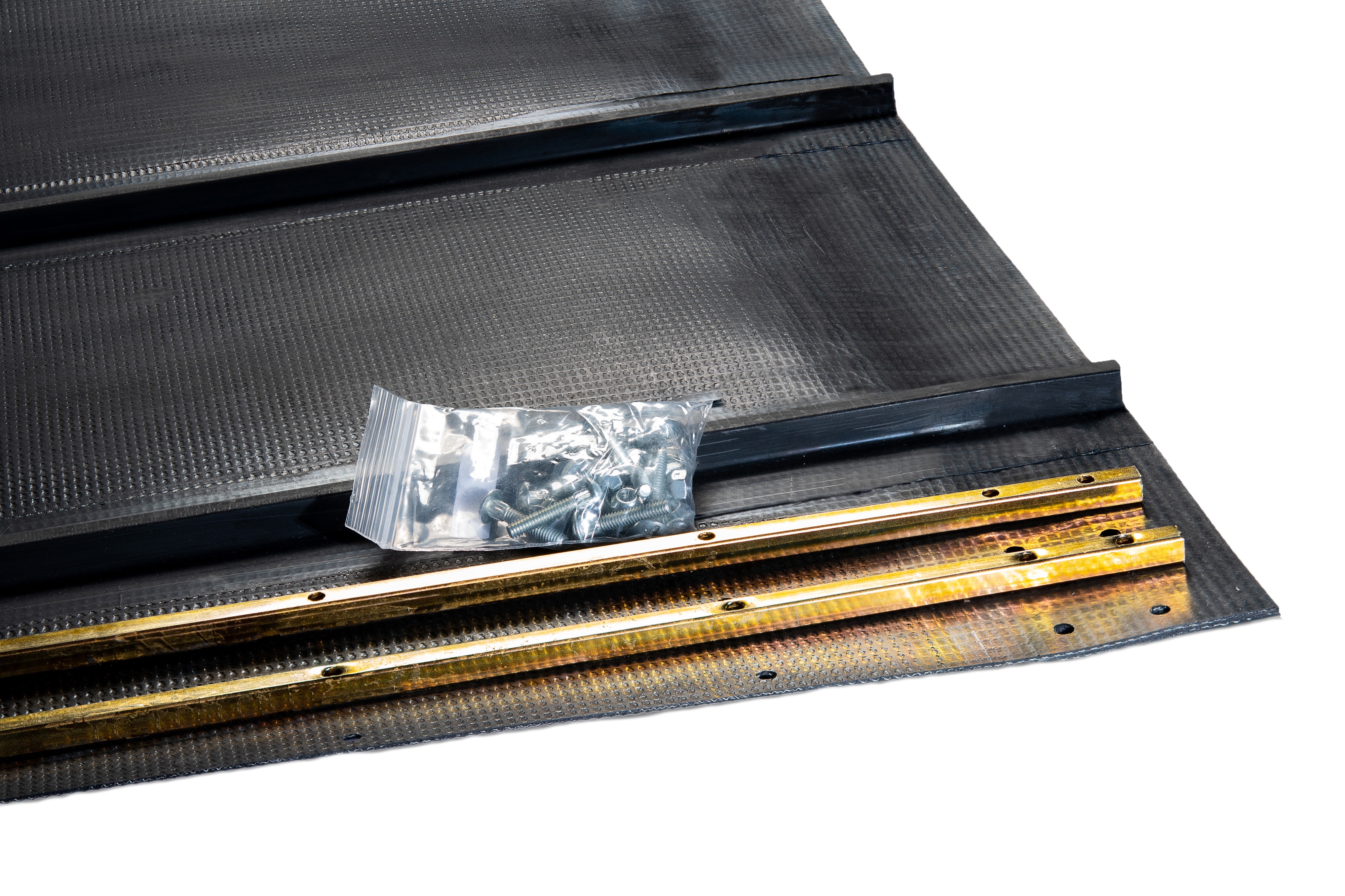

Draper header repair kits are a ready-to-install option for customers to extend the life of their draper belts and reduce downtime. Each draper repair kit includes 34” RAPTOR® draper material (two cleats) with holes punched on each end, and two steel tube connector assemblies. Original RAPTOR material supports belt uniformity and consistent specs throughout for preferred results. Pre-punched holes provide convenient connector installation and tracking.

Why do you offer repair kits?

We heard from OEMs of draper headers, and distributors for both types of belts, that they wanted to offer a quick fix for their customers if something happened mid-season. These repair kits offer step-by-step instructions and photos to help farmers patch their equipment on their own when needed.

In what instance would someone want to use the repair kit?

A few things can happen to a belt that can cause downtime during the season, creating issues for farmers. For draper headers, the most common issue is a belt tearing or getting a hole burned into it. If a hole is burned into the cured rubber, the best solution is to take out the portion of the belt that has been impacted instead of trying to patch it. There aren’t many people who will repair machinery anymore or patch holes, so this repair kit is a perfect option.

For baler belts, if the equipment runs into something which causes the belt to tear or rip, or if the belt is not tracking correctly and the splice catches the belt guides, it can cause the splice to tear out. If this happens, the farmer will need more material to add to the belt. We offer a six-foot piece of belting with two complete splices, which can repair two belts.

How easy is it to install the new belt?

We provide specific information to repair the belt, including a list of tools, step-by-step instructions and photos indicating how to fix both belts using the repair kit.

How long will the fixed belt last once it has been fixed?

If installed correctly, draper header belt repairs should last the expected lifetime of the original belt, so a new belt does not need to be ordered immediately. The belt life is shorter for baler belts, but with a correct installation, the belt should last the current season and into the next.

How can I order a repair kit?

Farmers in need of a repair kit should order through the dealership where they purchased the equipment. OEMs interested in purchasing repair kits can contact sales@wccobelt.com for more information.