"Beyond the Belt" with Brent Kohls, Kohls Farm

Brent Kohls is a fourth-generation farmer who runs the operation with his wife, Jennifer, and his in-laws. They raise corn and soybeans in addition to managing a seed distribution company. An active supporter of the state’s agricultural industry, Brent also spent nine years serving on the North Dakota Soybean Growers Association – a statewide, nonprofit, member-driven organization that conducts legislative activities aimed at improving sustainable prosperity of its members and the industry.

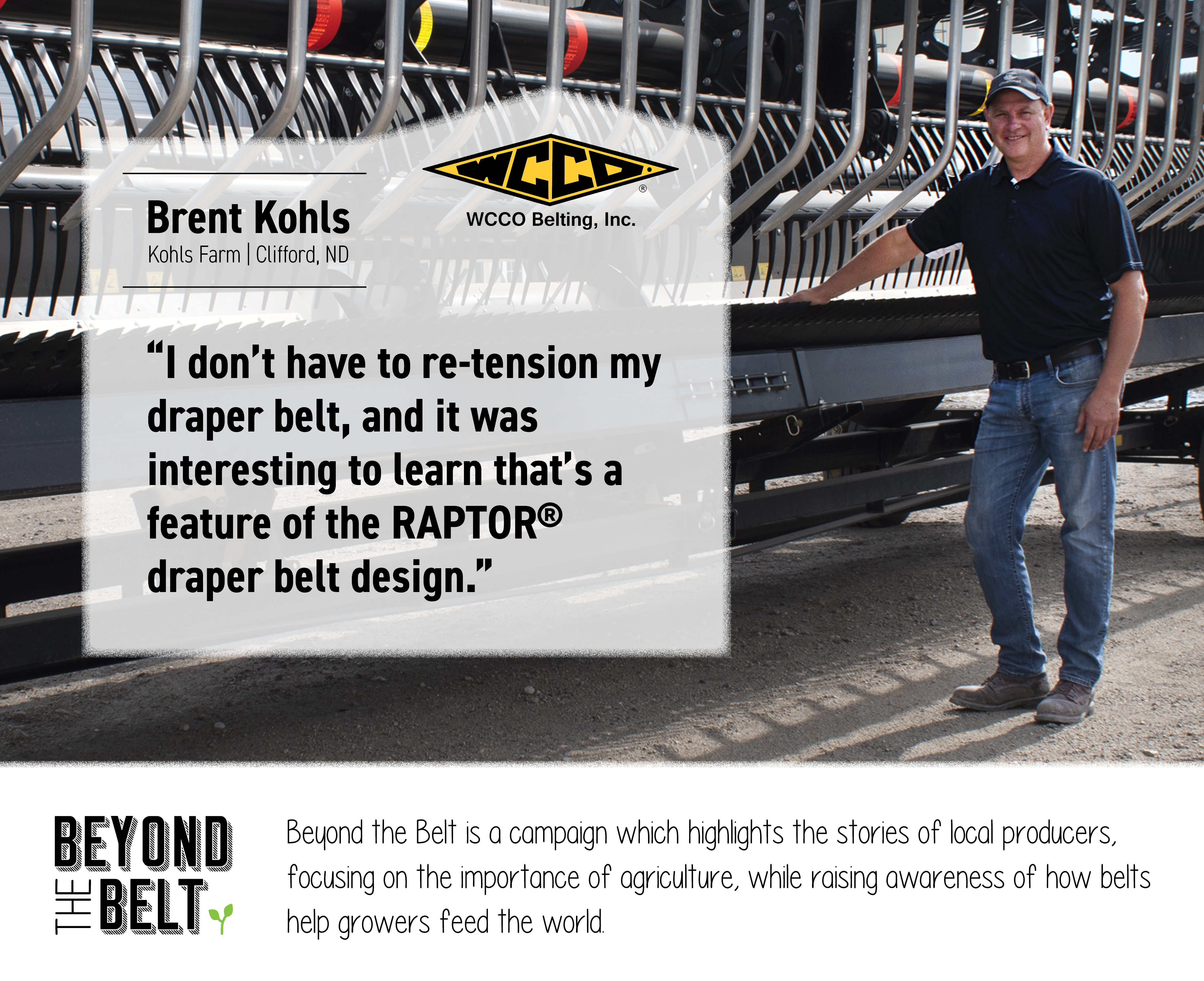

The WCCO team traveled to meet with Brent on his family’s farm on a bright, sunny morning this past June. Brent had a trailer holding a brand-new draper platform on display fitted with WCCO Belting’s patented RAPTOR® Draper Belting. He mentioned this wasn’t his first draper head, explaining that they switched from using augers to harvest their soybeans years ago and they’ve seen improvements in both crop quality and equipment performance since. “It makes a world of difference in the field with how evenly the draper belts feed.” When talking about the performance of RAPTOR® drapers, Brent also told us, “I don’t have to re-tension my draper belt, and it was interesting to learn that’s a feature of the RAPTOR® draper belt design.” That’s because the design of RAPTOR® eliminates downtime caused by re-tensioning due to its high strength fabric and a self-adjusting, patented fabric weave.

Next, we took a short walk over to Brent’s tube conveyor equipment. He told us he switched from augers to belted tube conveyors about ten years ago, “The big difference with belted tube conveyor belts is they are less trouble.” Brent also explained the benefits he recognizes as a seedsman for Channel Seed, “Belting is gentler and easier on the seed, which helps to preserve its quality.”

We asked Brent if he was familiar with tube conveyor belting that had cleats or paddles, and he walked us over to check out his seed tender. He explained that the original belt installed, which was not a WCCO product, did cause headaches and downtime. As soon as he told us the cleats were tearing off and getting stuck in the tube and planter, we took the opportunity to talk to Brent about the differences between a belt manufacturer – like WCCO – and fabricator.

His original belt was fabricated, meaning it was an existing belt construction that had cleats glued on its surface. Glue fails under stress, and the common result is cleat tearing. WCCO Belting is a belt manufacturer that uses a single-step vulcanization process to make cleated belting. The result is a belt that has integrally molded cleats which eliminates cleat tearing during operation. The proof is in the pudding, as the saying goes, because for the last three years Brent’s seed tender has been operating efficiently with a WCCO-made cleated conveyor belt. “Since replacing my belt with yours, I’ve had no issues with cleats falling off,” Brent said.

In the end, the WCCO team left Kohls Farm with a better understanding of how he relies on belting throughout different aspects of his family’s operation.

Brent, we hope we left you with useful information about your rubber belting products and the fellow North Dakota company who makes them. We are glad to count you as a satisfied customer. Thank you for your dedication to agriculture and helping to feed the world.